86-18603798888

86-18603798888 zhilibiao@hotmail.com

zhilibiao@hotmail.com

-

Brown Fused Alumina

Brown fused alumina is a high-quality abrasive grade bauxite as raw material, with accessories, in the electric arc furnace by 2250 ℃ high temperature refining,on the basis of secondary refining after high-intensity magnetic separator by impurity, refractoriness over 1850 ℃

-

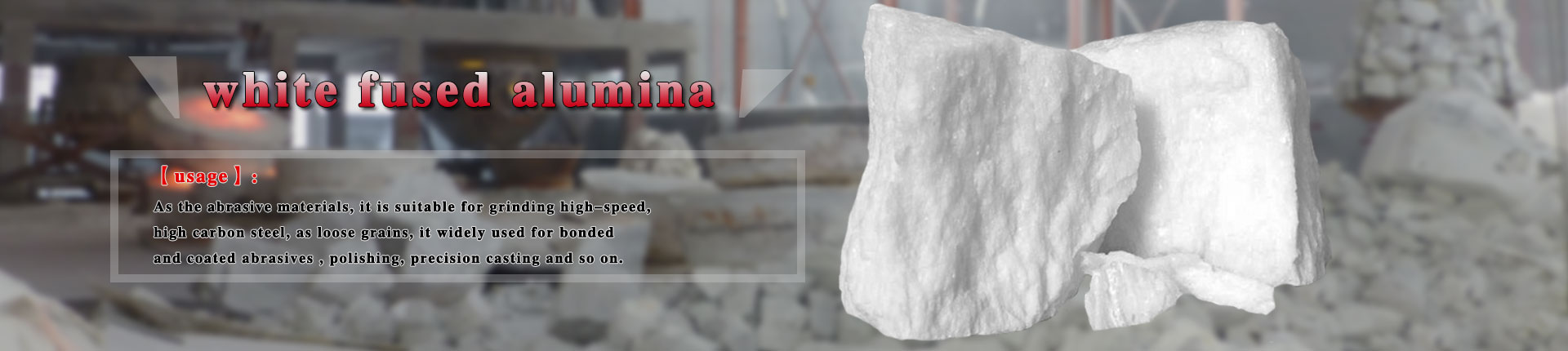

White fused alumina

White fused alumina is a high-quality aluminum oxide powder as raw material, the fused refining crystallization, high purity, good self-sharpening, acid corrosion,high temperature, hot performance and stability

-

Amorphous calcium aluminate / concrete additive / cement additive

Amorphous calcium aluminate is a new kind of quick-setting accelerator, its main ingredient is non-crystalline calcium aluminate, it is light gray green powder, it is used as fast setting cement additive (cement quick-setting admixture) and fast setting concrete additive(concrete quick-setting admixture )

-

Fused Calcium aluminate

Fused calcium aluminate, also known as Fused calcium aluminate,Refining slag, Premelting calcium aluminate,Refining sythetic slag mainly used to take off the molten steel sulfur, oxygen and other impurities

-

Sintered calcium aluminate

Sintering calcium aluminate also known as Refining slag Synthetic slag,because of its uniform composition,melting point of low,melting speed,can shorten the smelting time and other characteristics, mainly for steel refining and furnace refining

-

Ceramsite (Foundry sand)

RS Group ( Ceramic Foundry Sand Branch Plant) professionally produce Ceramic Foundry Sand It also named ( Ceramsite, Fused Ceramic, Ceramic Sand)

-

Fused Mullite

Mullite is a raw material with high heat resistance At present, there are mainly high purity fused mullite, ordinary fused mullite

-

Zirconia Fused Alumina

RS Brand Zirconia Fused Alumina of is produced by fusing rich aluminum, zirconium materials and additives in electric arc furnaces, smelting with high temperature above 2250℃

-

1、Mixing

All of the raw materials proportionately mixed together into the bin, then sent to the electric arc furnace for smelting

-

2、Smelting

In the power supply after the melting of ingredients by graphite electrode, then refining melting in arc furnace after more than 20 hours with more than 2250 ℃ high temperature refining made of corundum

-

3、Cooling

After natural cooling in 24 hours and water cooling, then formation of high-quality corundum block

-

4、Corundum grading

Break the furnace, pick out the qualified corundum block

-

5、Crushing process

With the crusher to carry out a variety of particle size of corundum sand (on the roller machine, ball mill, Bamak production line to be broken)

-

6、Separation

The production line is divided into a variety of particle size of corundum sand

-

7、Magnetic separator to impurities

Washing, dry cleaning, pickling

-

8、Technology

Washing, dry cleaning, pickling

-

9、mill powder

Making corundum powder with Raymond Mill

-

10、Sample test

Testing in the Laboratory

-

11、Package

For qualified products, packaging according to different grain size